Manufacturing prototypes and production parts quickly and cost-effectively is usually a balance between the rapid shift to CNC machining capabilities and optimized parts designed for these capabilities. Therefore, when designing parts for milling and turning processes, the following six important considerations can speed up production time while reducing costs.

1. Hole depth and diameter

In most cases, the hole is interpolated with an end mill, rather than drilled. This machining method provides great flexibility in the hole size of a given tool and provides a better surface finish than a drill. It also allows us to use the same tools to machine grooves and cavities, reducing cycle time and part costs. The only downside is that due to the limited length of the end mill, holes more than six diameters deep become a challenge and may require machining from both sides of the part.

2. Thread size and type

Drilling and thread making go hand in hand. Many manufacturers use “tap” to cut internal threads. The tap looks like a toothed screw and “screws” into the hole previously drilled. We use a more modern method to make threads, a tool called thread milling cutter to insert the thread profile. This allows precise threads to be created, and any thread size (threads per inch) that shares that pitch can be cut with a single milling tool, saving production and installation time.

3. Text on the part

Want to engrave the part number, description or logo on the part? Speed Plus supports most of the text required for processing, provided that the spacing between individual characters and the strokes used to “write” them are at least 0.020 inches (0.5 mm).

4. Wall height and characteristic width

All our cutting tools are made of cemented carbide cutting tools. This super-rigid material provides maximum tool life and productivity with minimal deflection. However, even the strongest tools can be deformed, as can metals, especially processed plastics. Therefore, the wall height and feature size are very dependent on the geometry of the individual parts and the tool set used.

5. Power tool lathe

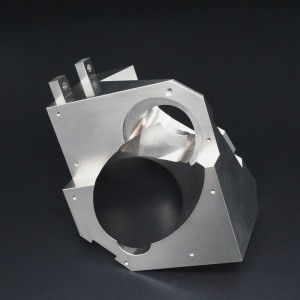

In addition to extensive milling capabilities, we also provide live tool CNC turning. The tool set used on these machines is similar to the tool set on our machining center, except that we do not turn plastic parts now. This means that eccentric holes, grooves, planes and other features can be machined parallel or perpendicular (axially or radially) to the “long axis” (its Z axis) of the turned workpiece, and usually follow orthogonal parts manufactured on a machining center The same design rules. The difference here is the shape of the raw material, not the tool set itself. Turned parts such as shafts and pistons are initially round, while milled parts such as manifolds, instrument boxes, and valve covers are usually not, but square or rectangular blocks are used.

6. Multi-axis milling

Using 3-axis machining, the workpiece is clamped from the bottom of the raw material blank, while all part features are cut from up to 6 orthogonal sides. The part size is greater than 10 inches * 7 inches (254 mm * 178 mm), only the top and bottom can be processed, no side setting! However, with five-axis indexing milling, machining can be performed from any number of non-orthogonal edges.

Post time: Nov-18-2021