Samfuran samfura da sassa na samarwa da sauri da tsada-tsari yawanci daidaituwa ne tsakanin saurin motsi zuwa ƙarfin injin CNC da ingantattun sassan da aka tsara don waɗannan damar.Sabili da haka, lokacin zayyana sassa don aikin niƙa da juyawa, mahimman la'akari guda shida masu zuwa na iya haɓaka lokacin samarwa yayin rage farashi.

1. Zurfin rami da diamita

A mafi yawan lokuta, ramin yana shiga tare da injin ƙarewa, maimakon hakowa.Wannan hanyar mashin ɗin yana ba da sassauci mai girma a cikin girman rami na kayan aikin da aka ba da shi kuma yana ba da kyakkyawan ƙarewa fiye da rawar soja.Hakanan yana ba mu damar amfani da kayan aikin iri ɗaya don injin ramuka da ramuka, rage lokacin sake zagayowar da farashin ɓangaren.Iyakar abin da ya rage shi ne saboda iyakacin iyaka na ƙarshen niƙa, ramuka fiye da diamita shida masu zurfi sun zama ƙalubale kuma yana iya buƙatar machining daga ɓangarorin biyu na ɓangaren.

2. Girman zaren da nau'in

Yin hakowa da zare suna tafiya hannu da hannu.Yawancin masana'antun suna amfani da "matsa" don yanke zaren ciki.famfo yana kama da dunƙule mai haƙori da “skru” a cikin ramin da aka haƙa a baya.Muna amfani da mafi zamani hanyar yin zaren, kayan aiki da ake kira zaren milling cutter don saka bayanan zaren.Wannan yana ba da damar ƙirƙirar madaidaicin zaren, kuma kowane girman zaren (zaren kowane inch) wanda ke raba wannan farar za a iya yanke shi da kayan aikin niƙa guda ɗaya, adana samarwa da lokacin shigarwa.

3. Rubutu a bangaren

Kuna so ku sassaƙa lambar ɓangaren, bayanin ko tambari a ɓangaren?Speed Plus yana goyan bayan yawancin rubutun da ake buƙata don sarrafawa, muddin tazara tsakanin haruffa ɗaya da bugunan da aka yi amfani da su don “rubuta” su aƙalla inci 0.020 (0.5 mm).

4. Tsayin bango da faɗin halayen

Dukkan kayan aikin mu na yankan kayan aikin siminti ne na yankan carbide.Wannan babban ƙaƙƙarfan abu yana ba da matsakaicin rayuwar kayan aiki da haɓaka aiki tare da ƙaramin juzu'i.Duk da haka, hatta kayan aikin da suka fi ƙarfi na iya zama naƙasasshe, kamar yadda ƙarfe, musamman robobi da aka sarrafa.Sabili da haka, tsayin bango da girman fasalin sun dogara sosai akan joometry na sassa daban-daban da kayan aikin da aka yi amfani da su.

5. Lathe kayan aikin wuta

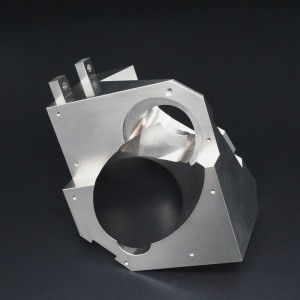

Baya ga iyawar niƙa mai yawa, muna kuma samar da kayan aikin CNC mai rai.Kayan kayan aikin da ake amfani da su akan waɗannan injunan yana kama da kayan aikin da aka saita a cibiyar injin mu, sai dai ba mu juya sassan filastik a yanzu.Wannan yana nufin cewa eccentric ramukan, tsagi, jiragen sama da sauran siffofi za a iya machined a layi daya ko perpendicular (axially ko radially) zuwa "dogon axis" (sa Z axis) na juya workpiece, kuma yawanci bi orthogonal sassa kerarre a kan wani machining cibiyar. dokokin ƙira iri ɗaya.Bambanci a nan shine siffar albarkatun kasa, ba kayan aikin da aka saita ba.Abubuwan da aka juya kamar su shafts da pistons suna zagaye da farko, yayin da sassa masu niƙa irin su manifolds, akwatunan kayan aiki, da murfin bawul yawanci ba, amma ana amfani da tubalan murabba'i ko rectangular.

6. Multi-axis milling

Yin amfani da 3-axis machining, workpiece an clamped daga kasa na albarkatun kasa m, yayin da duk sassa fasali an yanke daga sama zuwa 6 orthogonal bangarorin.Girman ɓangaren ya fi inci 10 * 7 inci (254 mm * 178 mm), sama da ƙasa kawai za a iya sarrafa su, babu saitin gefe!Koyaya, tare da milling na axis biyar, ana iya yin aikin injina daga kowane adadin gefuna waɗanda ba na orthogonal ba.

Lokacin aikawa: Nuwamba 18-2021