Kupanga ma prototypes ndi zida zopanga mwachangu komanso zotsika mtengo nthawi zambiri kumakhala koyenera pakati pa kusuntha mwachangu kupita ku luso la makina a CNC ndi magawo okongoletsedwa opangira maluso awa.Chifukwa chake, popanga magawo a mphero ndi kutembenuza, mfundo zisanu ndi imodzi zofunika zotsatirazi zitha kufulumizitsa nthawi yopanga ndikuchepetsa ndalama.

1. Kuzama kwa dzenje ndi m'mimba mwake

Nthawi zambiri, dzenje limalowetsedwa ndi mphero yomaliza, osati kubowola.Njira yopangira iyi imapereka kusinthasintha kwakukulu mu kukula kwa dzenje la chida chopatsidwa ndipo imapereka kutha kwapamwamba kuposa kubowola.Zimatithandizanso kugwiritsa ntchito zida zomwezo popanga ma grooves ndi ma cavities, kuchepetsa nthawi yozungulira komanso ndalama zina.Choyipa chokha ndichakuti chifukwa cha kutalika kochepa kwa mphero yomaliza, mabowo opitilira ma diameter asanu ndi limodzi amakhala ovuta ndipo angafunike kukonza mbali zonse za gawolo.

2. Kukula kwa ulusi ndi mtundu

Kubowola ndi kupanga ulusi kumayendera limodzi.Opanga ambiri amagwiritsa ntchito "tap" kudula ulusi wamkati.Kumpopiko kumawoneka ngati zomangira zokhala ndi mano ndi "zomangira" mu dzenje lomwe linabowoleredwa kale.Timagwiritsa ntchito njira yamakono kupanga ulusi, chida chotchedwa thread milling cutter kuti tiyike mbiri ya ulusi.Izi zimalola kuti ulusi wolondola upangidwe, ndi kukula kwa ulusi uliwonse (zingwe pa inchi) zomwe zimagawana phulalo likhoza kudulidwa ndi chida chimodzi cha mphero, kupulumutsa nthawi yopanga ndi kukhazikitsa.

3. Lembani pa mbali

Mukufuna kulemba nambala ya gawo, malongosoledwe kapena logo pagawolo?Speed Plus imathandizira zolemba zambiri zomwe zimafunikira kuti zisinthidwe, malinga ngati kusiyana pakati pa zilembo ndi mikwingwirima yomwe amagwiritsidwa ntchito "kuwalemba" ndi osachepera 0.020 mainchesi (0.5 mm).

4. Kutalika kwa khoma ndi m'lifupi mwake

Zida zathu zonse zodulira zidapangidwa ndi zida zodulira simenti ya carbide.Zinthu zolimba kwambirizi zimapereka moyo wa zida zambiri komanso zokolola zosasinthika pang'ono.Komabe, ngakhale zida zamphamvu kwambiri zimatha kupunduka, monganso zitsulo, makamaka mapulasitiki opangidwa.Chifukwa chake, kutalika kwa khoma ndi kukula kwa mawonekedwe kumadalira kwambiri geometry ya magawo omwewo komanso zida zomwe zimagwiritsidwa ntchito.

5. Mphamvu chida lathe

Kuphatikiza pa kuthekera kwakukulu kwa mphero, timaperekanso chida chamoyo CNC kutembenuka.Chida chomwe chimagwiritsidwa ntchito pamakinawa ndi chofanana ndi chida chomwe chili pamalo athu opangira makina, kupatula kuti sititembenuza magawo apulasitiki tsopano.Izi zikutanthauza kuti ma eccentric mabowo, grooves, ndege ndi zina zimatha kupangidwa mofananira kapena perpendicular (axially kapena radially) ku "axis yaitali" (Z axis) ya workpiece yotembenuzidwa, ndipo nthawi zambiri amatsatira mbali za orthogonal zomwe zimapangidwa pamalo opangira makina. malamulo mapangidwe ofanana.Kusiyana apa ndi mawonekedwe a zopangira, osati chida kudziyika yokha.Zigawo zotembenuzidwa monga ma shafts ndi ma pistoni poyamba zimakhala zozungulira, pomwe zida zopukutidwa monga ma manifolds, mabokosi a zida, ndi zovundikira ma valve nthawi zambiri sizikhala, koma midadada yamakona kapena yamakona anayi imagwiritsidwa ntchito.

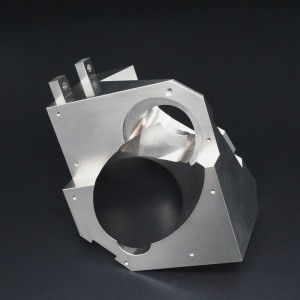

6. Mipikisano axis mphero

Pogwiritsa ntchito makina a 3-axis, chogwiriracho chimamangidwa kuchokera pansi pazitsulo zopanda kanthu, pamene mbali zonse zimadulidwa kuchokera ku mbali 6 za orthogonal.Kukula kwa gawo ndi kwakukulu kuposa mainchesi 10 * 7 mainchesi (254 mm * 178 mm), pamwamba ndi pansi zokha zitha kukonzedwa, palibe kuyika mbali!Komabe, ndi mphero ya ma-axis asanu, makina amatha kuchitidwa kuchokera kumagulu aliwonse omwe si a orthogonal.

Nthawi yotumiza: Nov-18-2021