BXD provides efficient and fast production CNC turning services

From complex CNC turned parts to high volume mass production, BXD is your CNC Turning partner. Our range of metal and plastics includes aluminum, steel, PP, ABS etc. Simply tell us what you need then trust BXD to manage the whole process for you. We will offer precision CNC turned parts at affordable prices .

What is CNC Turning?

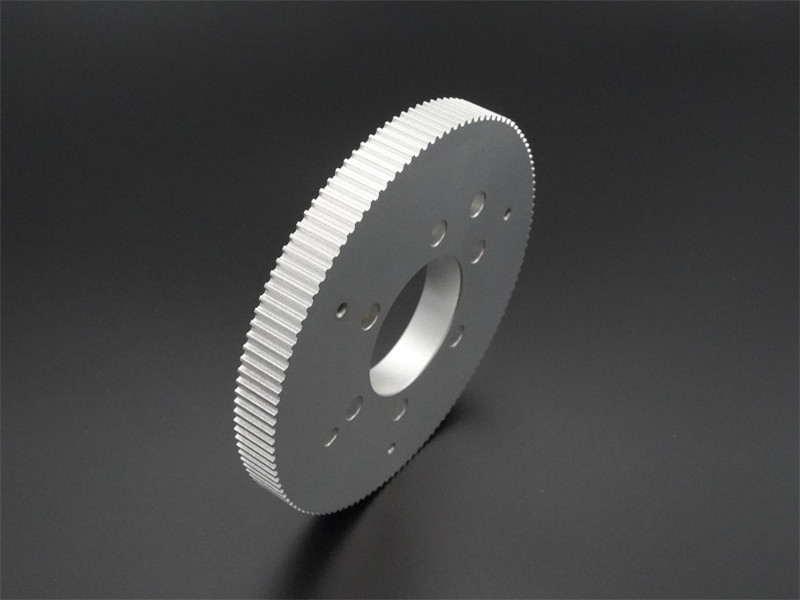

CNC turning, also commonly referred to as CNC lathe, it is a subtractive manufacturing process that removes material from a rotating cylindrical geometry resulting in a symmetrical cross-section.

CNC turning operations are designed for making final parts with axial and radial holes, internal diameters, grooves and slots. It can produce parts at a much higher rate and at a lower cost unit than CNC milling, especially for larger volumes.

How Does CNC Turning work?

CNC turning is usually used to produce parts with a cylindrical profile. During CNC turning operation, the workpiece is held on the spindle while rotating at a high speed, a cutting tool or center drill traces the outer and inner perimeter of the parts forming the geometry. Holes along the center axis can also be manufactured using central drills and internal cutting tools. The cutting tool will typically move along the X, Y and Z axis relative to the part.

CNC Turning Materials

BXD CNC turning center offer a wide selection of materials from prototyping to full production. We are capable of high-speed turning for both metals and plastics to create end-parts with complex external geometries, cylindrical features, threads and internal bores. For turning parts you can choose the materials from aluminum, brass, low carbon steel, stainless steel, steel alloy, titanium etc.