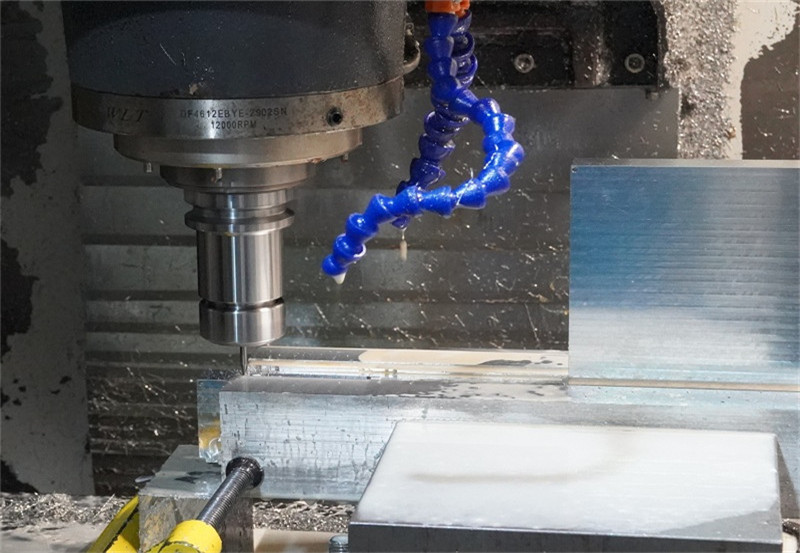

BXD provides a variety of precision CNC machining services including milling, turning, EDM (electrical discharge machining) and wire EDM, surface grinding, laser engraving and much more. With our precision 3-, 4- and 5-axis CNC machining centers, combined with other advanced capabilities and our experienced team, we can provide prototypes and small volume machine parts in tight lead time and high quality, so your team can focus on bringing your product to market.

CNC can machine a wide range of materials to meet your needs (ceramic, plastic, wood, metal, composite, foam and glass), and can be used across a wide array of industries. We also offer a lot of second machining and surface finishing service, such as painting, silk printing, brushing, plating, polishing, sandblasting, anodizing and so on. At BXD, our CNC machining process is widely applied in new product development, rapid tooling, product prototyping and end-product manufacturing.

If you need a precision machining company for plastic and metal CNC machining parts, BXD is the best place to go.

CNC machining manufacturer - BXD

What is CNC Machining?

The term CNC widely refers to the “computer numerical control” technology that is used in the subtractive manufacturing process. CNC machining is a manufacturing technology involving the use of computer-aided controls and machine tools to remove layers/portions of a stock material/workpiece till a desired custom and final part is made from the workpiece.

CNC machining - Milling (3-, 4- & 5-axis)

CNC lathe- Turning machine

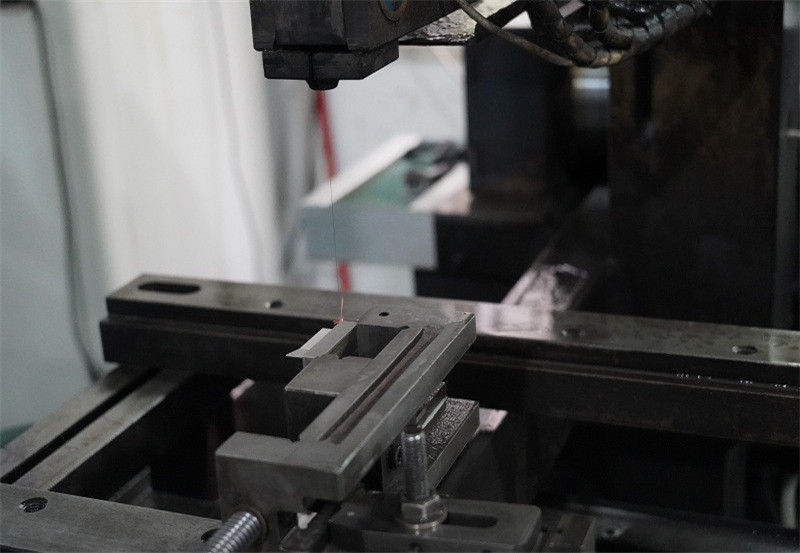

Wire EDM

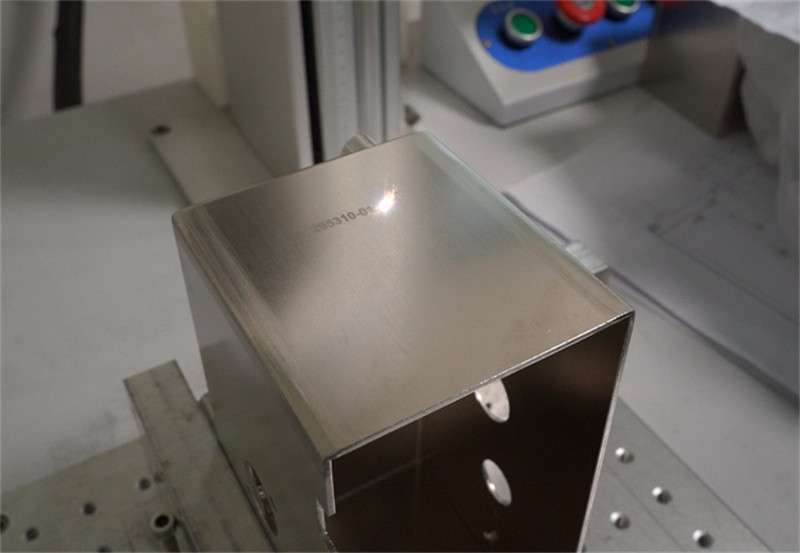

Laser marking

Surface finishing

The surface treatment process involves clear anodize, black anodized, passivation, clear chromate conversion, clear anodize, electroplating, high speed sand blasting, high polished, deburring, smooth, superficial wiredrawing, etc.

The surface finishing types include: rose gold, gun color, chromium, nickel, etc.

Our surface treatment performance tests can meet or exceed industry standards.

Processing equipment:

CNC machining center, CNC lathe, CNC milling machine, CNC turning machine, precision grinder, EDM, wire EDM, drilling machine, tapping machine, rivet machine, laser marking machine, ultrasonic cleaning machine,3D CMM etc.

Industries Of CNC Machining

CNC turning and milling operations are of utmost importance in many industries and economic sectors. Some of the industries where CNC machining is widely applied are listed below:

What materials are available for CNC Machining?

Plastic: ABS, PC, ABS+PC, PP, PS, POM, PMMA (Acrylic), PAGF30, PCGF30, Teflon, DHPE, HDPE, PPS, PEEK etc.

Metal: Aluminum, Steel, Stainless Steel (17-4, Inconel 625 & 718), Magnesium, Titanium, Zinc, Brass, Bronze, Copper etc.

These are the most common materials for CNC prototyping and production parts. If the desired material is not listed above, please contact our team.

EDM / Wire EDM and Surface Grinding

-Electrical discharge machining (EDM) is an essential manufacturing process used primarily on tool steels for plastic injection molding or pressure die casting. EDM uses a conductive graphite or copper electrode submerged in a dielectric bath of water or oil. When a high voltage current is applied to the electrode it sparks against the tool wall, etching away at the surface to produce deep holes, ribs, undercuts and surface textures that are difficult to machine conventionally. When done properly, EDM can produce excellent surface finishes with tight tolerances, virtually eliminating the need for secondary polishing.

-Surface grinding is an automated machining process used to make extremely flat and smooth surfaces. In this method, the workpiece is held in a fixture and then reciprocated across the face of a precision grinding wheel.

CNC Machining Tolerances

We are able to provide stand tolerance CNC machined parts with the most economic price and super precision machined parts for the high-end products. When working with BXD, we guarantee all parts will be made accordingly to your specification.

|

Tolerance Standard |

|||||||

| Tolerance Lever |

Overall Dimension Range |

||||||

| Specifications | <<3, >0.5 | <<6, >3 | <<30, >6 | <<120, >30 | <<400, >120 | <<1000, >400 | <<2000,>1000 |

| F | ±0.05 | ±0.05 | ±0.1 | ±0.15 | ±0.2 | ±0.3 | ±0.5 |

| M | ±0.1 | ±0.1 | ±0.2 | ±0.3 | ±0.5 | ±0.8 | ±1.2 |

| C | ±0.2 | ±0.3 | ±0.5 | ±0.8 | ±1.2 | ±2 | ±3 |

| V | – | ±0.5 | ±1 | ±1.5 | ±2.5 | ±4 | ±6 |

3D CAD FILE TYPES

Please export your 3D CAD files to STEP, IGS or PARASOLID format.

3D's Format: STEP(.step, .stp), Solidworks(.sldprt), Pro/E(.prt), Inventor(.ipt), CATIA(.CATPart), ACIS(.x_t)

2D DRAWINGS

We highly recommend sending separate PDF Engineering Drawings for each part.

Annotated screenshots can sometimes be accepted.

Please indicate any threaded holes, critical dimensions and tolerances.

Please communicate material and finishing requirements (if applicable).

2D's format: dwg, dxf, pdf or zip the files send to us

Why choose BXD for CNC Machining Services?

With over 10 years’ experience in CNC and general machining services, BXD is one of the best CNC machining services manufacturer in China. Here’s the reason:

1. Fast Turnaround

On average we return quotes within 24 hours, parts ship within 7 days or less, and we have a 99% on-time delivery and quality rate.

2. Experiences

Our engineers have been providing CNC machining services for over 10 years and have built up rich experiences from many previous projects, we can handle complex and precision parts without problem.

3. Complete Equipment with stable supply chain

BXD has extensive in-house equipment for both manufacturing and testing. We will provide stable supply chain for one-stop machining services for you from raw materials to finish products.

Want a quote? Contact us now.

Request a free quote today and we will personally review your project within 24 hours.