Quality Assurance of BXD

Quality is the strong guarantee for the development of the company, obviously, production processing is the key to product quality, inspection is the guarantee for the products. BXD has been strictly followed SOP for production process. Our stable and qualified products have earned our customers' trust for years.

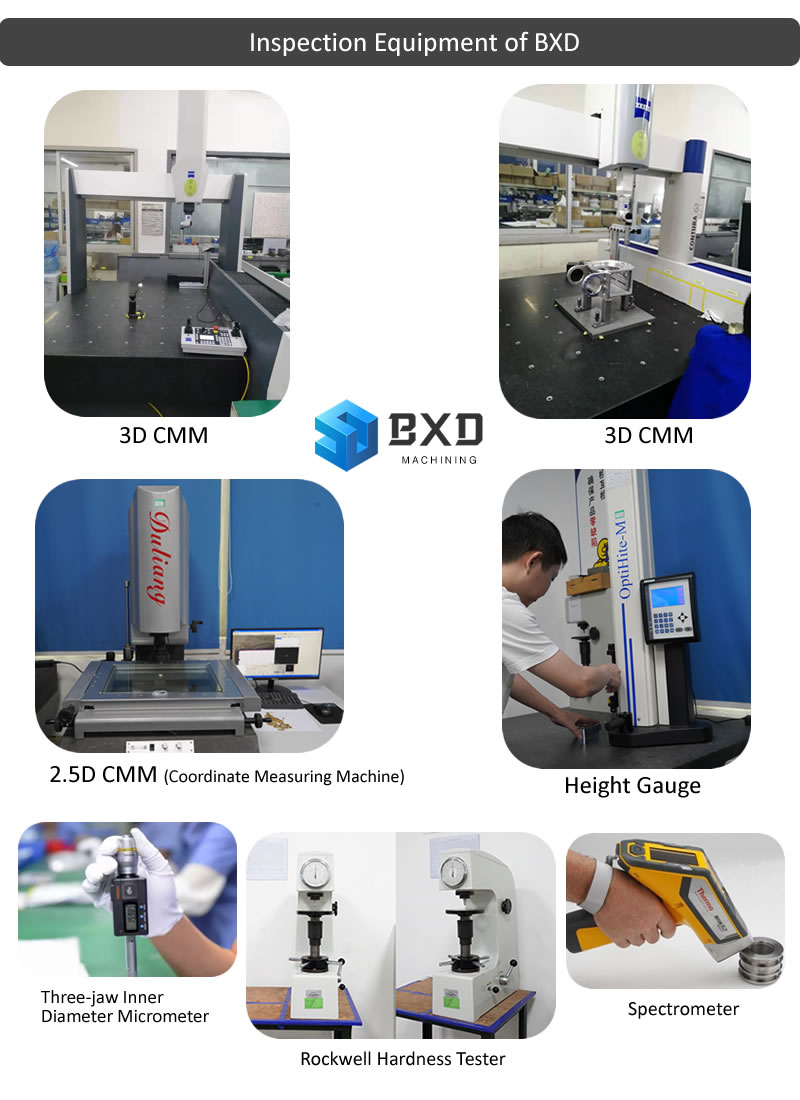

Inspection Equipment

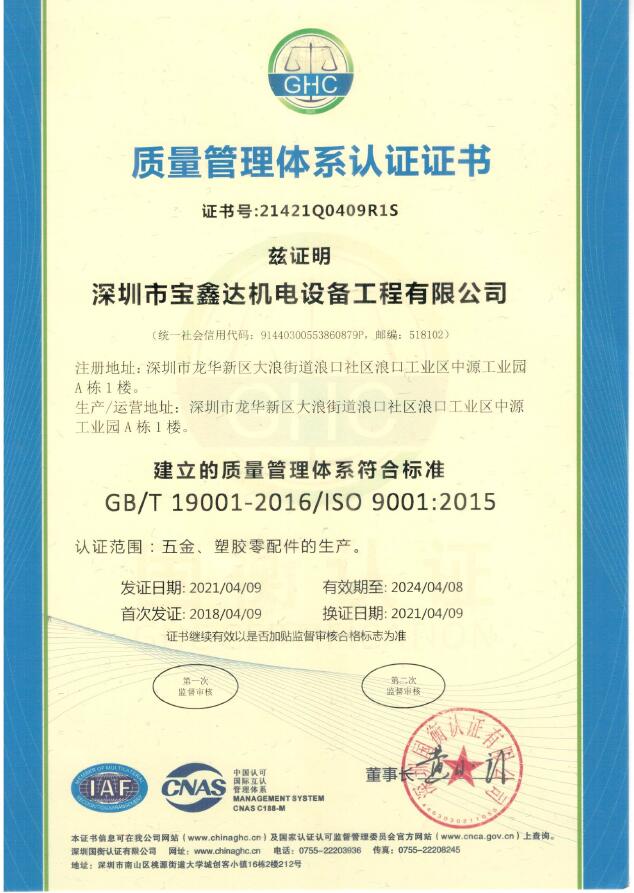

BXD has always paid attention to the construction and development of quality. We have passed the ISO9001:2015 quality management system certification. We continues to improve and increase testing equipment.

Test equipment are: 3D CMM, altimeter, hardness tester, salt spray testing equipment, film thickness meter, vernier caliper, inner diameter micrometer, outer micrometer, projector, pin hole detection special needle gauge, standard tooth gauge (pass stop gauge ), and other equipments.

Test Contents after Production

During production, our company strictly performs processing, production and testing according to customer requirements. The test contents include: salt spray test, adhesion test, coating (paint) film thickness test, hardness test, waterproof test, anti-static test, electrical conductivity test, vibration Test, high and bottom temperature test, special function test, material composition test, color sample comparison block, etc. Product inspection will be accompanied by a factory inspection report with the product according to customer requirements.

Inspection Process:

In BXD CNC machining, inspection and quality control are the most important process in order to make a high quality product. Inspection and quality control ensures the standard quality by checking the product during manufacturing at different stages.

To make sure the products conform to our customers' requirements, from raw material to shipment, every step of the manufacturing process is under control. All products will be under 3 checks in the whole process:

1. Raw material inspection: check the raw material before accepting and storing

2. In-line inspection: technicians do self-check for every parts and QC spot check during production.

3. Final inspection: QC 100% inspect the finished product before shipping and choose the best packaging way to avoid damages during transportation.

CNC Machining Standards

We follow ISO 2768 standards for CNC Machining.

Our team is dedicated to making sure all parts you order are delivered on time and meet your quality expectations.