Ukukhiqiza ama-prototypes nezingxenye zokukhiqiza ngokushesha nangendlela engabizi kakhulu kuvame ukulingana phakathi kokushintshela ngokushesha kumakhono womshini we-CNC kanye nezingxenye ezithuthukisiwe ezidizayinelwe lawa makhono.Ngakho-ke, lapho uklama izingxenye zezinqubo zokugaya nokuguqula, ukucatshangelwa okulandelayo okuyisithupha okubalulekile kungasheshisa isikhathi sokukhiqiza ngenkathi kunciphisa izindleko.

1. Ukujula kwembobo nobubanzi

Ezimweni eziningi, umgodi uhlanganiswa nesigayo sokuphela, kunokuba ubhojwe.Le ndlela yokwenza imishini inikeza ukuguquguquka okukhulu kusayizi wembobo yethuluzi elinikeziwe futhi inikeza isiphetho esingcono kakhulu kunomshini wokubhoboza.Kuphinde kusivumele ukuthi sisebenzise amathuluzi afanayo womshini ama-grooves nama-cavities, ukunciphisa isikhathi somjikelezo kanye nengxenye yezindleko.Okuwukuphela kwecala elibi ukuthi ngenxa yobude obulinganiselwe begayo lokugcina, izimbobo ezingaphezu kwamadayamitha ayisithupha ukujula ziba inselele futhi zingase zidinge umshini ovela ezinhlangothini zombili zengxenye.

2. Usayizi womucu kanye nohlobo

Ukubhoboza nokwenza intambo kuyahambisana.Abakhiqizi abaningi basebenzisa "kampompi" ukusika izintambo zangaphakathi.Umpompi ubukeka njengesikulufu esinamazinyo futhi "ufaka izikulufu" embobeni ebhojwe ngaphambilini.Sisebenzisa indlela yesimanjemanje ukwenza imicu, ithuluzi elibizwa nge-thread milling cutter ukufaka iphrofayili yochungechunge.Lokhu kuvumela ukuthi kudalwe imicu enembayo, futhi noma imuphi usayizi wentambo (imicu ngeyintshi ngayinye) owabelana ngalelo zwi lingasikwa ngethuluzi elilodwa lokugaya, konga isikhathi sokukhiqiza nesokufaka.

3. Umbhalo engxenyeni

Ingabe ufuna ukuqopha inombolo yengxenye, incazelo noma ilogo engxenyeni?I-Speed Plus isekela umbhalo omningi odingekayo ukuze kucutshungulwe, inqobo nje uma isikhala phakathi kwezinhlamvu ezingazodwana kanye nama-stroke asetshenziselwa "ukubhala" okungenani amayintshi angu-0.020 (0.5 mm).

4. Ubude bodonga nobubanzi besici

Wonke amathuluzi ethu okusika enziwe ngamathuluzi okusika i-carbide enosimende.Lokhu okuqinile okuqinile kunikeza impilo yamathuluzi ephezulu kanye nokukhiqiza ngokuchezuka okuncane.Nokho, ngisho namathuluzi aqine kakhulu angakhubazeka, kanjalo nezinsimbi, ikakhulukazi amapulasitiki agayiwe.Ngakho-ke, ukuphakama kodonga nosayizi wesici kuncike kakhulu kujometri yezingxenye ngazinye kanye nesethi yamathuluzi asetshenzisiwe.

5. I-lathe yethuluzi lamandla

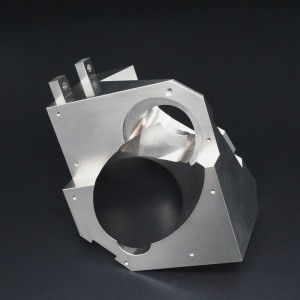

Ngokungeziwe emandleni abanzi okugaya, siphinde sinikeze ithuluzi elibukhoma le-CNC turning.Isethi yamathuluzi esetshenziswa kule mishini ifana nethuluzi elibekwe esikhungweni sethu somshini, ngaphandle kokuthi asizishintshi izingxenye zepulasitiki manje.Lokhu kusho ukuthi izimbobo ezi-eccentric, ama-grooves, izindiza nezinye izici zingenziwa ngomshini ngokuhambisana noma i-perpendicular (i-axially noma i-radially) ukuya "ku-eksisi ende" (i-axis yayo engu-Z) ye-workpiece ephendukile, futhi ngokuvamile ilandela izingxenye ze-orthogonal ezikhiqizwa esikhungweni somshini. imithetho efanayo yokuklama.Umehluko lapha ukuma kwempahla eluhlaza, hhayi ithuluzi elizisethe ngokwalo.Izingxenye eziphendukile njengama-shaft nama-pistons ekuqaleni ziyindilinga, kuyilapho izingxenye ezigayiwe ezinjengama-manifold, amabhokisi wezinsimbi, namakhava amavalvu ngokuvamile akuzona, kodwa kusetshenziswa amabhulokhi ayisikwele noma angunxande.

6. Ukugaya ama-multi-eksisi

Ngokusetshenziswa kwemishini ye-3-axis, ucezu lokusebenza luboshiwe kusukela phansi kwempahla eluhlaza engenalutho, kuyilapho zonke izici zisikwa kusukela ezinhlangothini ezi-6 ze-orthogonal.Usayizi wengxenye mkhulu kunama-intshi angu-10 * 7 amayintshi (254 mm * 178 mm), kuphela phezulu nangaphansi okungacutshungulwa, akukho kulungiselelwa ohlangothini!Kodwa-ke, ngokugaywa kokukhomba kwe-axis emihlanu, ukukhanda kungenziwa kusuka kunoma iyiphi inombolo yamaphethelo angewona ama-orthogonal.

Isikhathi sokuthumela: Nov-18-2021