Precision Aluminum Alloy 6061 CNC Milling Parts with Nickel Plating

This is a socket used in automation equipment for holding the Lithium battery, It is made of 6061 aluminum alloy, which is very hard and durable. The surface is plated with nickel which can resist the corrosion of atmosphere, alkali and some acids. It can maintain its luster for a long time in the atmosphere. The hardness of nickel coating is relatively high, which can improve the wear resistance of product surface.

| Material | Aluminum Alloy 6061 |

| Surface treatment | Sandblasting oxidation, anodic oxidation, natural oxidation, hard oxidation |

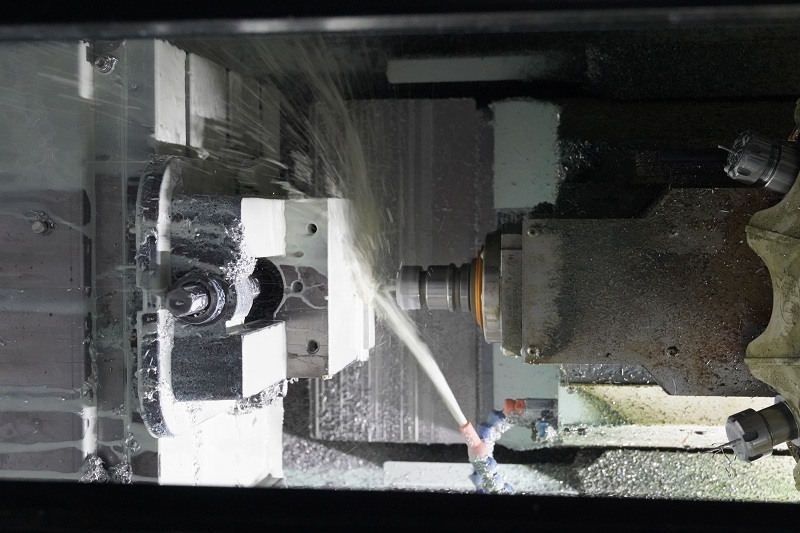

| Production processing | CNC machining, CNC milling, Tapping, surface finish |

| Industry | Medical industry, automation equipment industry |

| Tolerance | +/- 0.01mm |

| Drawing format | jpg / pdf / dxf / dwg / step / stp / igs / x_t / prt etc. |

| Quality assurance | - Raw material inspection: Check the raw material before accepting and storing. - In-line inspection: technicians do self-check for every parts and QC spot check during production. - Final inspection: QC 100% inspect the finished product before shipping. |

| MOQ | 1pcs |

| Sample lead time | Common products 1-10 days after received drawing and payment |

| Shipping & Delivery | By Express or By air according to customer’s requirement |

Product: Aluminum 6061 holder for automation equipment

Processes: CNC machining, CNC milling, Tapping

Surface finishing: Hard anodizing

Product: Aluminum 6061 fixture for automation equipment

Processes: CNC machining, CNC milling, Tapping

Surface finishing: Sandblasting oxidation

BXD is an ISO9001:2015 certified manufacturer, we provides a variety of precision CNC machining services including milling, turning, EDM, wire EDM, surface grinding and more, with our precision 3-, 4- and 5-axis CNC machining centers and testing equipments. We can provide prototypes and low-volume machine parts with high quality in short lead time. If you need a precision machining company for plastic and metal CNC machining parts, BXD is the best place to go.

At present, the standard and non-standard products of our company's customers have been widely used in the automotive field, communication equipment, intelligent robot matching, medical equipment, industry 4.0 automation equipment, drones, smart toys, various LED lamps and smart Household products, etc. It can independently and satisfactorily meet the high precision and high decorative requirements of customers.

Looking for a reliable, quick-turn supplier of machined plastic and metal parts? With complete equipments, we ensure your parts are shipped on-time, every single time.