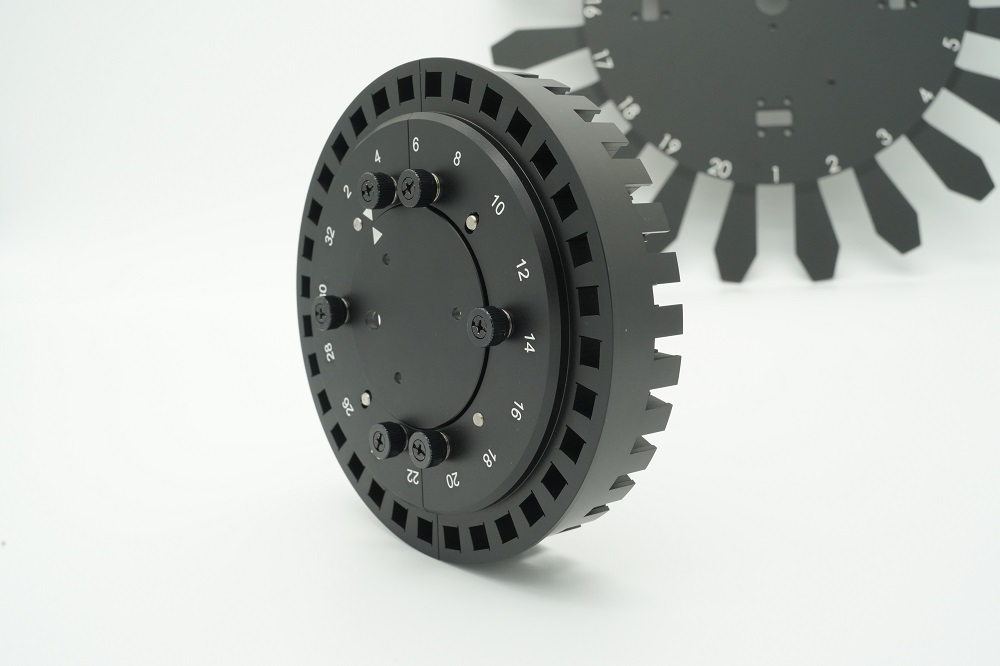

CNC Turning Parts Aluminum Alloy 6061 For Medical Devices

This is a feeding box used in medical equipment. It is made of 6061 aluminum alloy, which is very hard and durable. The surface with sandblasting oxidation which makes the workpiece smooth and non-reflective.

| Material | Aluminum Alloy 6061 |

| Surface treatment | Sandblasting oxidation |

| Production processing | CNC turning, CNC machining, wire-EDM, surface finishing, laser marking, Pressure riveting screws |

| Industry | Medical industry |

| Tolerance | +/- 0.01mm |

| Drawing format | jpg / pdf / dxf / dwg / step / stp / igs / x_t / prt etc. |

| Quality assurance | - Raw material inspection: Check the raw material before accepting and storing. - In-line inspection: technicians do self-check for every parts and QC spot check during production. - Final inspection: QC 100% inspect the finished product before shipping. |

| MOQ | 1pcs |

| Sample lead time | Common products 1-10 days after received drawing and payment |

| Shipping & Delivery | By Express or By air according to customer’s requirement |

CNC Turning

CNC Machining for hole and slots

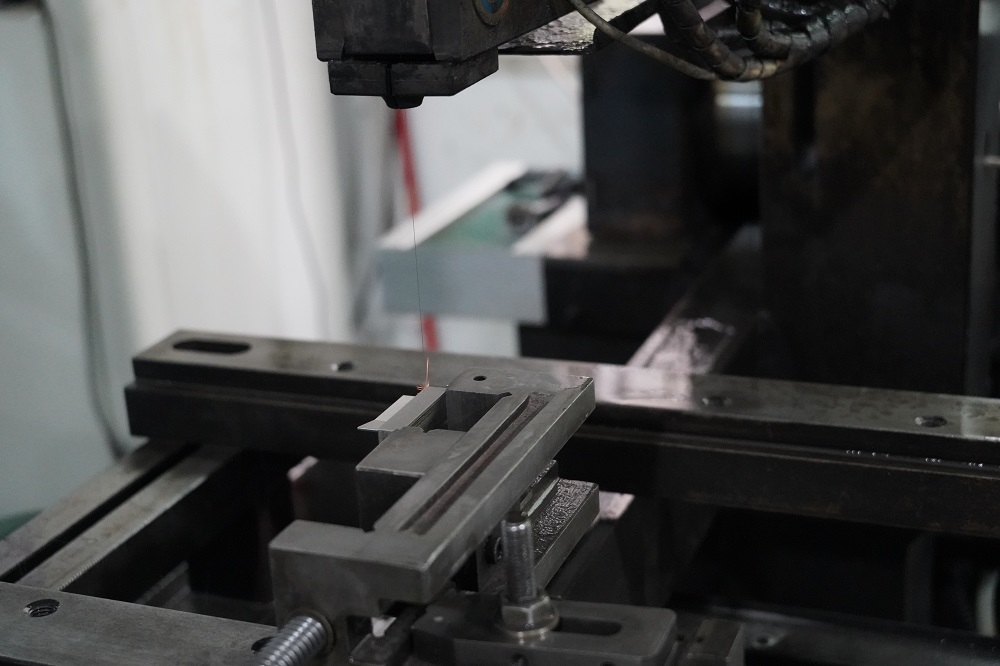

Wire EDM

Wire EDMLaser marking

BXD is capable to provide cost-effective CNC turning lathe services and quality products with high precision and accuracy for vast projects.

Low, medium to high volume batches production run

Rapid prototyping and end-use manufacturing

High dimensional accuracy, high speed and high reliability

A wide range of compatible metal and plastics materials

Great productivity and improved efficiency

Smooth finishes and tight tolerances can be achieved

Shenzhen BXD Machining Co., Ltd

At BXD, our team of expert engineers and designers helps large and small companies around the world to make the world’s best prototypes and precision parts. We work with all kinds of engineers, product designers, and entrepreneurs from a wide range of industries like automotive, medical devices, automation equipment, aerospace, consumer & commercial products.

Please contact us with confidence.