News

-

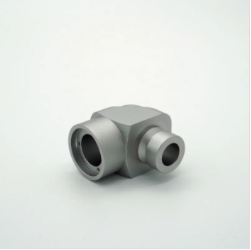

What are the characteristics of CNC machining

Process concentration, automation, high flexibility, and strong capabilities are the characteristics of CNC machining. The process rules of CNC machine tool processing and traditional machine tool processing are generally consistent, but there have also been significant changes. So what are the c...Read more -

Four characteristics of CNC machining

1. The degree of automation is high, and the production efficiency is very high. Except for blank clamping, all other processing operations can be completed by CNC machine tools. If combined with the automatic loading and unloading method, it is a basic part of the unmanned control factory. CNC m...Read more -

What does cnc machining do

Numerically controlled (CNC) machining is a manufacturing process that many industries have incorporated into their manufacturing processes. This is because the use of CNC machines can increase production. It also allows for a wider range of applications than manually operated machinery. The oper...Read more -

How does CNC lathe processing aluminum materials ensure dimensional accuracy?

First of all, under the premise of aluminum material, the following aspects must be considered: 1. Force majeure factors: 1. The stability of the CNC lathe itself. If it is not for the new CNC lathe or the CNC lathe has not been adjusted after a lot of production and processing, there will be a s...Read more -

Why CNC machining is critical to the robotics industry

Robots seem to be everywhere these days – in movies, in airports, in food production, and even in factories that make other robots. Robots have many different functions and uses, and as they become easier and cheaper to manufacture, they are also becoming more commonplace in industry. As th...Read more -

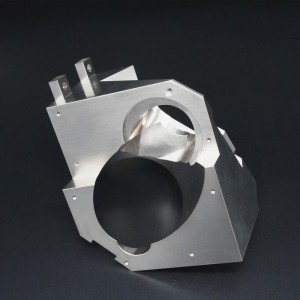

6 ways to optimize the design of CNC machined parts

Prototyping and production parts quickly and cost-effectively is often a balance between a quick turn to CNC machining capabilities and optimized parts designed for those capabilities. So here are 6 important considerations when designing parts for milling and turning processes that can speed up ...Read more -

Several points to improve the quality of CNC machining workpieces

Several prominent points to improve the quality of CNC machining workpieces: 1. Reasonable use of turning and milling machining tools for copper and aluminum parts The smooth knives for processing steel and copper should be strictly distinguished and used, and the allowance of the smooth knives s...Read more -

Explain the safety rules and operation points of CNC four-axis machining

1. Safety rules for CNC four-axis machining: 1) The safety operation rules of the machining center must be followed. 2) Before work, you should wear protective equipment and tie your cuffs. Scarves, gloves, ties, and aprons are not allowed. Female workers should wear braids in hats. 3...Read more -

The division of CNC lathe processing procedures

In CNC lathe machining parts, the process should generally be divided according to the principle of process concentration, and the processing of most or even all surfaces should be completed as much as possible under one clamping. According to the different structural shapes of the parts, the out...Read more -

Basic maintenance method of CNC machining center

CNC machining center has a very wide range of applications, and it is also a kind of equipment that is often used in the field of precision machining. When using a machining center, whether it is before, during or after use, the corresponding maintenance items cannot be ignored. , Hongweisheng Pr...Read more -

Main features and specific applications of CNC machining CNC machine tools

Main features and specific applications of CNC machine tools CNC machine tools have very important precision requirements in the production process of parts, and also have very important requirements for production efficiency. The requirements of CNC machining CNC machine tools are that they can ...Read more -

What are the advantages and disadvantages of CNC machining

General CNC machining usually refers to computer digital control precision machining, CNC machining lathes, CNC machining milling machines, CNC machining boring and milling machines, etc. CNC is also called computer gong, CNCCH or CNC machine tool. It is a new type of processing technology, and i...Read more