News

-

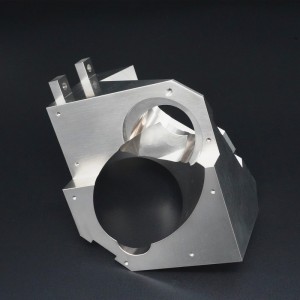

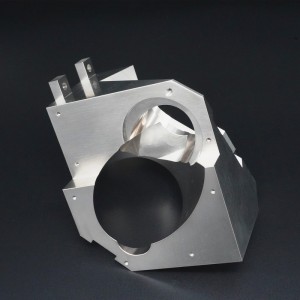

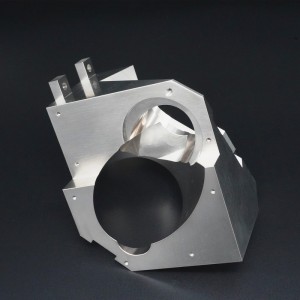

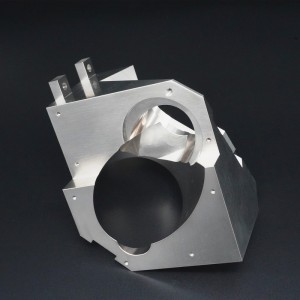

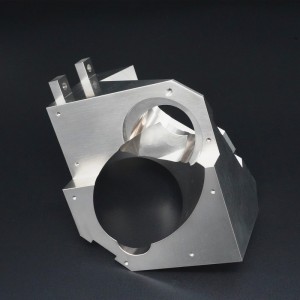

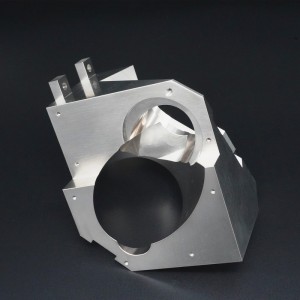

6 ways to optimize the design of CNC machined parts

1. Hole depth and diameter Holes in most cases are interpolated with end mills, not drilled. This machining method offers great flexibility in hole size for a given tool and provides a better surface finish than drills. It also allows us to machine grooves and cavities with the same tool, reducin...Read more -

The advantages and development trend of CNC machining

CNC, as its name implies, is a method of computer-based digital control, using digital information to control machine tool movement and processing processes. It has a high-speed, reliable, multi-functional, intelligent and open structure development structure It is also an important indicator to ...Read more -

CNC post-processing

The hardware surface processing subdivision can be divided into: hardware oxidation processing, hardware painting processing, electroplating, surface polishing processing, hardware corrosion processing, etc. Surface processing of hardware parts: 1. Oxidation processing: When the hardware factory ...Read more -

What are the benefits of CNC machining tool cutting front and rear corners?

Precision parts processing companies know that the direct and effective way to reduce processing costs is to effectively apply turning to different parts of CNC tools. Therefore, in order to choose a suitable CNC tool, in addition to selecting the appropriate tool material, it is also necessary t...Read more -

Three quick tips for CNC tools and machining

Understanding how the geometry of the part determines the machine tool required is an important part of minimizing the number of settings a mechanic needs to perform and the time it takes to cut the part. This can speed up the part manufacturing process and save you costs. Here are 3 tips about C...Read more -

Functions and features of CNC machining

In addition to the characteristics of ordinary milling machine processing, CNC milling processing also has the following characteristics: 1. The parts have strong adaptability and flexibility, and can process parts with particularly complex contour shapes or difficult to control size, such as mol...Read more -

What are the requirements for the division of CNC machining processes?

When CNC machining processes are divided, it must be flexibly controlled based on the structure and manufacturability of the parts, the functions of the CNC machining center machine tool, the number of parts CNC machining content, the number of installations and the production organization of the...Read more -

Basic knowledge of CNC precision hardware parts processing

In the mass production of CNC precision hardware parts processing, because the workpiece requires high precision and short delivery time, the efficiency of the equipment is the top priority of the production and processing. Being able to grasp simple basic knowledge can not only improve the produ...Read more -

CNC machining should pay attention to daily product maintenance and maintenance

There are various products in people’s lives, so that they can get a good product use mode and operation process, and better meet their actual use needs. For mechanical products, not only must pay attention to the correct operation process, especially the daily maintenance , after a period ...Read more -

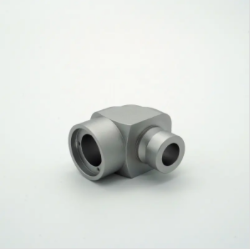

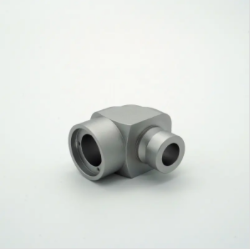

What are the CNC machining processes and advantages?

According to the original conditions such as the part drawing and process requirements, the part numerical control processing program is compiled and input to the numerical control system of the numerical control machine tool to control the relative movement of the tool and the workpiece in the n...Read more -

6 ways to optimize the design of CNC machining parts

Manufacturing prototypes and production parts quickly and cost-effectively is usually a balance between the rapid shift to CNC machining capabilities and optimized parts designed for these capabilities. Therefore, when designing parts for milling and turning processes, the following six important...Read more -

CNC machining steps

CNC machining is currently the mainstream machining method. When we perform CNC machining, we must not only know the characteristics of CNC machining, but also know the steps of CNC machining, so as to better improve machining efficiency, then CNC machining What are the processing steps? 1. Analy...Read more