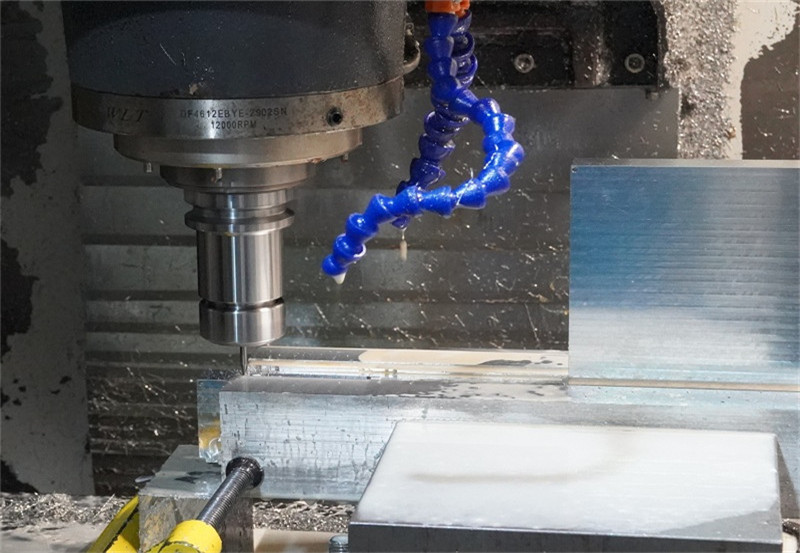

BXD e fana ka mefuta e fapaneng ea lits'ebeletso tsa machining tsa CNC tse nepahetseng tse kenyelletsang ho sila, ho reteleha, EDM (machining ea ho ntša motlakase) le terata EDM, ho sila ka holim'a metsi, laser engraving le tse ling tse ngata.Ka litsi tsa rona tsa machining tsa CNC tse nepahetseng tsa 3-, 4- le 5-axis, li kopantsoe le bokhoni bo bong bo tsoetseng pele le sehlopha sa rona se nang le boiphihlelo, re ka fana ka li-prototypes le likarolo tse nyane tsa mochini oa molumo ka nako e thata le boleng bo holimo, kahoo sehlopha sa hau se ka tsepamisa maikutlo ho tlisa. sehlahiswa sa hao ho ya mmarakeng.

CNC e ka kenya lisebelisoa tse ngata ho fihlela litlhoko tsa hau (ceramic, polasetiki, lehong, tšepe, composite, foam le khalase), 'me e ka sebelisoa ho pholletsa le mefuta e mengata ea liindasteri.Re boetse re fana ka ts'ebeletso e ngata ea bobeli ea machining le ea ho qeta holim'a metsi, joalo ka ho penta, khatiso ea silika, brushing, plating, polishing, sandblasting, anodizing joalo-joalo.Ho BXD, ts'ebetso ea rona ea mochini oa CNC e sebelisoa haholo ho nts'etsopele ea sehlahisoa se secha, lisebelisoa tse potlakileng, prototyping ea sehlahisoa le tlhahiso ea sehlahisoa sa ho qetela.

Haeba u hloka k'hamphani ea machining e nepahetseng bakeng sa likarolo tsa machining tsa polasetiki le tšepe tsa CNC, BXD ke sebaka se setle ka ho fetisisa seo u ka eang ho sona.

Moetsi oa mochini oa CNC - BXD

CNC Machining ke eng?

Lentsoe CNC le bua haholo ka theknoloji ea "taolo ea linomoro tsa khomphutha" e sebelisoang ts'ebetsong ea tlhahiso ea subtractive.CNC machining ke theknoloji ea tlhahiso e kenyelletsang tšebeliso ea lisebelisoa tsa lisebelisoa tsa k'homphieutha le lisebelisoa tsa mochine ho tlosa likarolo / likarolo tsa thepa ea thepa / workpiece ho fihlela tloaelo e lakatsehang le karolo ea ho qetela e etsoa ho tloha mosebetsing.

CNC machining - Milling (3-, 4- & 5-axis)

CNC lathe- Mochini o fetolang

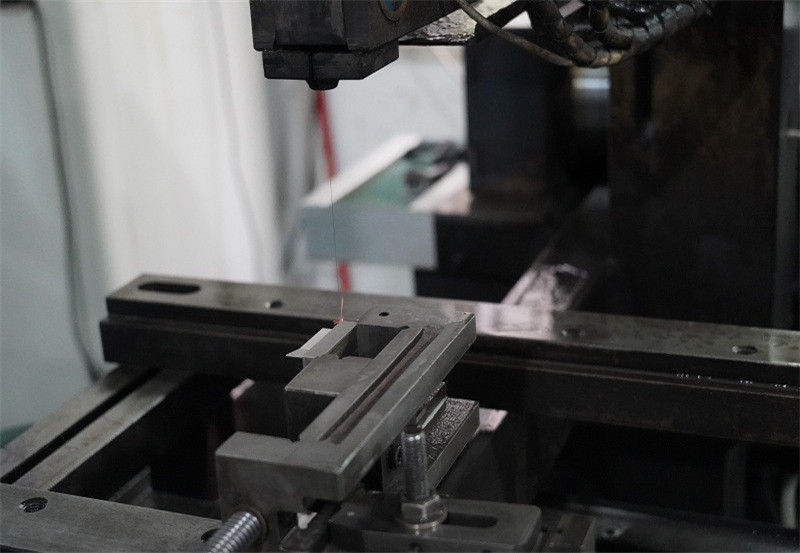

EDM ea mohala

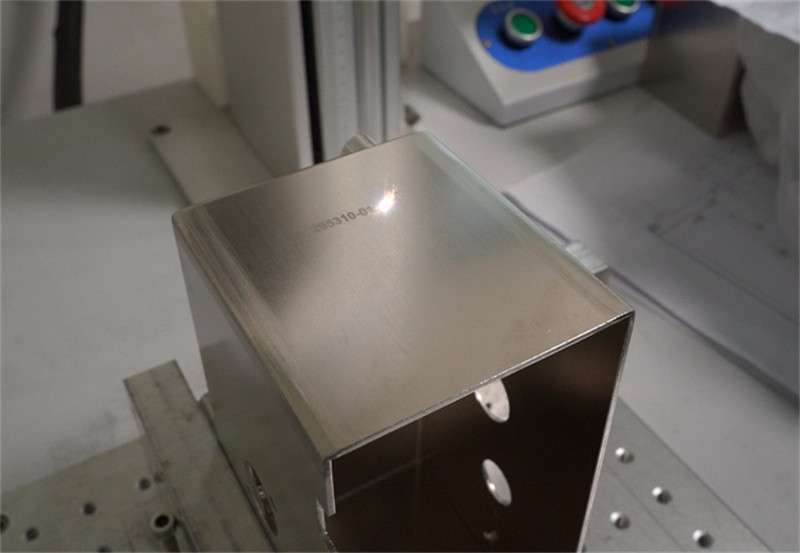

Ho tšoaea ka laser

Ho qeta bokahodimo

Ts'ebetso ea kalafo ea bokaholimo e kenyelletsa anodize e hlakileng, anodized e ntšo, passivation, phetoho e hlakileng ea chromate, anodize e hlakileng, electroplating, ho phatloha ha lehlabathe ka lebelo le phahameng, pholisitsoeng e phahameng, ho senya, ho boreleli, ho thaepa mohala ka holimo, joalo-joalo.

Mefuta ea ho qeta bokaholimo e kenyelletsa: khauta ea rose, 'mala oa sethunya, chromium, nickel, joalo-joalo.

Liteko tsa rona tsa ts'ebetso ea kalafo ea holim'a metsi li ka kopana kapa tsa feta litekanyetso tsa indasteri.

Lisebelisoa tsa ho sebetsa:

CNC machining center, CNC lathe, CNC milling machine, CNC turning machine, precision grinder, EDM, wire EDM, mochini oa ho phunya, mochini oa rivet, mochini oa ho tšoaea laser, mochini oa ho hloekisa oa ultrasonic, 3D CMM joalo-joalo.

Liindasteri tsa CNC Machining

Ts'ebetso ea ho fetola CNC le ho sila e bohlokoa haholo liindastering tse ngata le makaleng a moruo.Tse ling tsa liindasteri moo mochini oa CNC o sebelisoang haholo li thathamisitsoe ka tlase:

Ke lisebelisoa life tse teng bakeng sa CNC Machining?

Plastiki:ABS, PC, ABS + PC, PP, PS, POM, PMMA (Acrylic), PAGF30, PCGF30, Teflon, DHPE, HDPE, PPS, PEEK joalo-joalo.

Tšepe:Aluminium, Steel, Stainless Steel (17-4, Inconel 625 & 718), Magnesium, Titanium, Zinki, Brass, Bronze, Copper joalo-joalo.

Tsena ke lisebelisoa tse atileng haholo bakeng sa prototyping ea CNC le likarolo tsa tlhahiso.Haeba boitsebiso bo lakatsehang bo sa thathamisoa ka holimo, ka kopo ikopanye le sehlopha sa rona.

EDM / Wire EDM le Surface Grinding

-Electrical discharge machining (EDM) ke ts'ebetso ea bohlokoa ea tlhahiso e sebelisoang haholo-holo holim'a litšepe tsa lisebelisoa bakeng sa ho bopa ente ea polasetiki kapa khatello ea die cast.EDM e sebelisa graphite ea conductive kapa electrode ea koporo e kenngoeng ka har'a bateng ea dielectric ea metsi kapa oli.Ha motlakase o phahameng o sebelisoa ho electrode, e thunya khahlanong le lebota la lisebelisoa, e thella holim'a metsi ho hlahisa masoba a tebileng, likhopo, li-undercuts le libopeho tse ka holimo tseo ho leng thata ho li etsa ka mokhoa o tloaelehileng.Ha e etsoa hantle, EDM e ka hlahisa likhahla tse ntle ka ho fetisisa tse nang le mamello e thata, hoo e batlang e felisa tlhokahalo ea ho belisoa ha bobeli.

-Ho sila ka holim'a metsi ke mokhoa o ikemetseng oa mochini o sebelisetsoang ho etsa libaka tse bataletseng haholo le tse boreleli.Ka mokhoa ona, workpiece e ts'oaroa ka mokhoa o ts'oanang ebe e khutlisetsoa sefahlehong sa lebili le silang le nepahetseng.

CNC Machining Tolerances

Re khona ho fana ka likarolo tse entsoeng ka mochini oa CNC ka theko e phahameng ka ho fetisisa ea moruo le likarolo tse entsoeng ka mokhoa o nepahetseng haholo bakeng sa lihlahisoa tse phahameng haholo.Ha re sebetsa le BXD, re netefatsa hore likarolo tsohle li tla etsoa ho latela litlhaloso tsa hau.

| MamelloStloaelehileng | |||||||

| Tolerance Lever | Kakaretso ea Dimension Range | ||||||

| Litlhaloso | <<3,>0.5 | <<6,>3 | <<30,>6 | <<120,>30 | <<400,>120 | <<1000,>400 | <<2000,>1000 |

| F | ±0.05 | ±0.05 | ±0.1 | ±0.15 | ±0.2 | ±0.3 | ±0.5 |

| M | ±0.1 | ±0.1 | ±0.2 | ±0.3 | ±0.5 | ±0.8 | ±1.2 |

| C | ±0.2 | ±0.3 | ±0.5 | ±0.8 | ±1.2 | ±2 | ±3 |

| V | - | ±0.5 | ±1 | ±1.5 | ±2.5 | ±4 | ±6 |

3D CAD MEFUTA FELE

Ka kopo, romela lifaele tsa hau tsa 3D CAD ho STEP, IGS kapa PARASOLID format.

3D's Format:MOHATO(.step, .stp), Solidworks(.sldprt), Pro/E(.prt), Inventor(.ipt), CATIA(.CATPart), ACIS(.x_t)

LITŠOANTŠISO TSA 2D

Re khothaletsa haholo ho romella Metako ea Boenjiniere ea PDF e arohaneng bakeng sa karolo ka 'ngoe.

Lits'oants'o tsa skrini ka linako tse ling li ka amoheloa.

Ka kopo, bonts'a masoba a khoele, litekanyo tse mahlonoko le mamello.

Ka kopo, buisana le litlhoko tsa ho qetela (haeba ho hlokahala).

2D sebopeho:dwg, dxf, pdf kapa zip lifaele tseo re li romellang

Hobaneng u khetha BXDbakeng sa Litšebeletso tsa Machining tsa CNC?

Ka boiphihlelo ba lilemo tse fetang 10 ho CNC le lits'ebeletso tse akaretsang tsa machining, BXD ke e 'ngoe ea baetsi ba litšebeletso tsa machining tsa CNC tse ntle ka ho fetisisa China.Lebaka ke lena:

1. Phetoho e potlakileng

Ka karolelano re khutlisa mantsoe a qotsitsoeng nakong ea lihora tse 24, likarolo li romelloa nakong ea matsatsi a 7 kapa ka tlase, 'me re na le 99% ea ho fana ka nako le sekhahla sa boleng.

2. Liphihlelo

Baenjineri ba rona esale ba fana ka lits'ebeletso tsa mochini oa CNC ka lilemo tse fetang 10 mme ba thehile liphihlelo tse ntle ho tsoa mererong e mengata e fetileng, re khona ho sebetsana le likarolo tse rarahaneng le tse nepahetseng ntle le bothata.

3.FeletsengThepaka ketane ea phepelo e tsitsitseng

BXD e na le lisebelisoa tse ngata tsa ka tlung bakeng sa ho etsa le ho etsa liteko.Re tla fana ka ketane ea phepelo e tsitsitseng bakeng sa lits'ebeletso tsa mochini o le mong bakeng sa hau ho tloha lisebelisoa tse tala ho fihlela lihlahisoa.

U batla tlhahiso?Ikopanye le rona hona joale.

Kopa tlhahiso ea mahala kajeno 'me re tla hlahloba morero oa hau pele ho lihora tse 24.