China High-Quality CNC Machining Auto Parts Factories Company – Pure Copper Mini Precision CNC Machining Parts with Gold Plating – BXD

China High-Quality CNC Machining Auto Parts Factories Company – Pure Copper Mini Precision CNC Machining Parts with Gold Plating – BXD Detail:

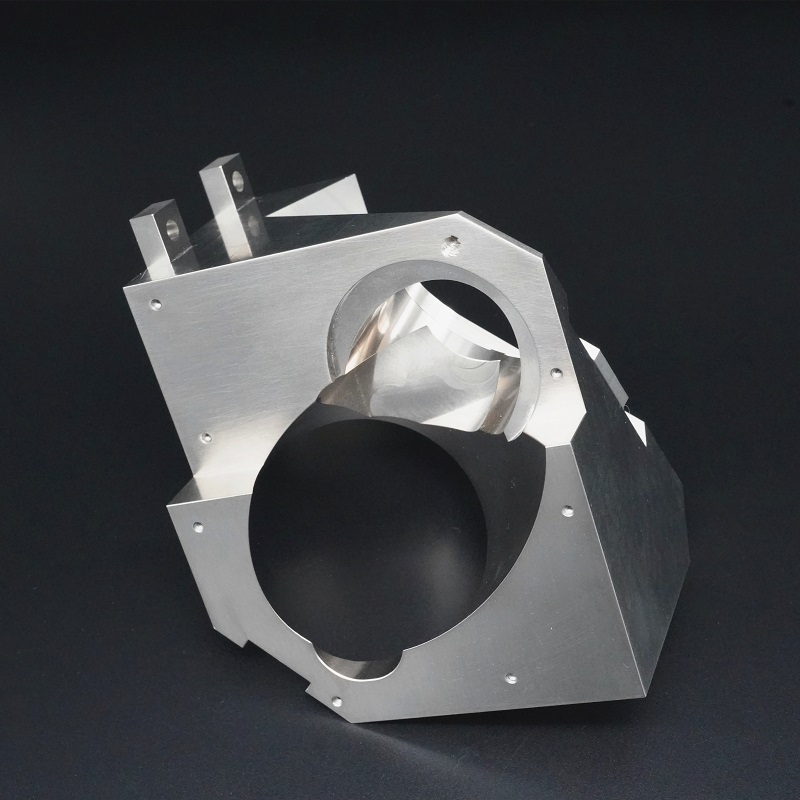

This is a precision mini clamp used in an advanced laser equipment.

| Material | Pure Copper |

| Surface treatment | Gold plating |

| Production processing | CNC machining, tapping, surface finishing |

| Industry | Medical industry |

| Tolerance | +/- 0.01mm |

| Drawing format | jpg / pdf / dxf / dwg / step / stp / igs / x_t / prt etc. |

| Quality assurance | - Raw material inspection: Check the raw material before accepting and storing. - In-line inspection: technicians do self-check for every parts and QC spot check during production. - Final inspection: QC 100% inspect the finished product before shipping. |

| MOQ | 1pcs |

| Sample lead time | Common products 1-10 days after received drawing and payment |

| Shipping & Delivery | By Express or By air according to customer’s requirement |

Metals: Aluminum, Brass, Copper, Stainless Steel, Steel Alloy, Steel Mild Low Carbon, Titanium

Plastics: ABS, Acetal, CPVC, HDPE, LDPE, Nylon, PEEK, PEI, PET, PMMA, Polycarbonate, Polypropylene, PPSU, PS, PSU, PTFE, PVC

BXD CNC machining service is a quick and cost-effective approach to manufacture high-grade prototypes and high-precision end use parts of engineering-grade materials.At BXD, our CNC machining process is widely applied in new product development, product prototyping and low volume production, end-product manufacturing. It is suitable for use with an diverse range of materials (ceramic, plastic, wood, metal, composite, foam and glass), and can be used across a wide array of industries.

This is the clamp without surface finishing (copper):

Size of this machined part:

Product detail pictures:

Related Product Guide:

Dependable high-quality and fantastic credit standing are our principles, which will help us at a top-ranking position. Adhering to your tenet of "quality very first, client supreme" for China High-Quality CNC Machining Auto Parts Factories Company – Pure Copper Mini Precision CNC Machining Parts with Gold Plating – BXD , The product will supply to all over the world, such as: Moldova , Irish , Rome , After 13 years of researching and developing products, our brand can represent wide range of products with outstanding quality in world market. We have completed big contracts from many countries such as Germany, Israel, Ukraine, United Kingdom, Italy, Argentina, France, Brazil, and so on. You probably feel secure and satisfy when copperate with us.

This is a honest and trustworthy company, technology and equipment are very advanced and the prodduct is very adequate, there is no worry in the suppliment.