Ho tla ba le liphetho tse fapaneng tsa sefahleho, ho kenyelletsa:

- Ho sila

- Ho benya

- Ho phatloha ha Bead

- Electroplating

- Knurling

- Honing

- Anodising

- Chrome Plating

- Ho roala ka phofo

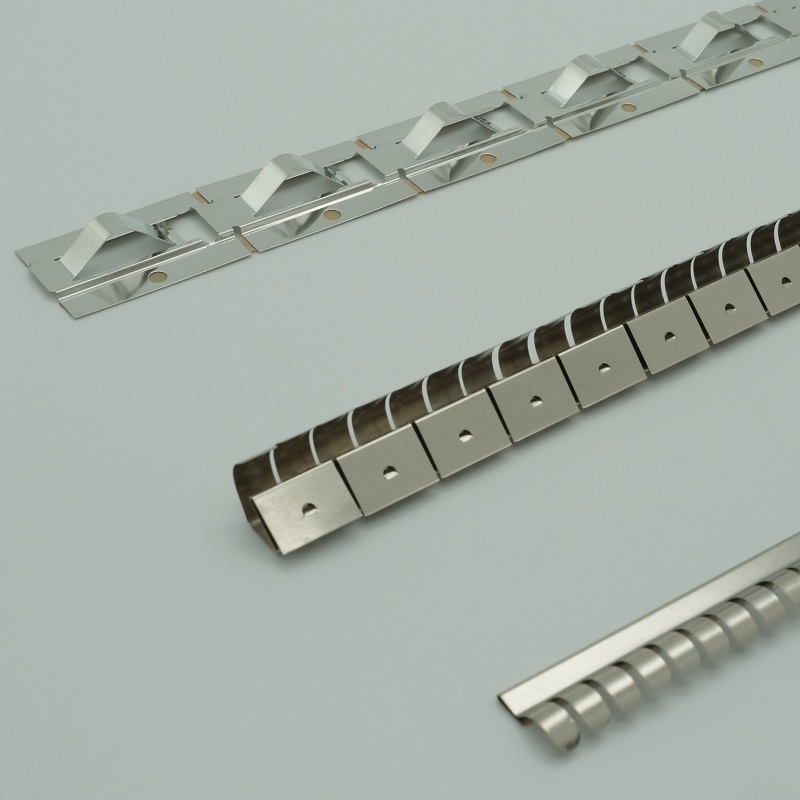

Metal surface processing e ka aroloa ka:ts'ebetso ea oxidation ea tšepe, ts'ebetso ea ho penta ka tšepe, electroplating, ho bentša holim'a metsi, ho sebetsa ha tšepe, joalo-joalo.

Ho phethoa ha likarolo tsa Hardware:

1. Ts'ebetso ea oxidation:Ha fektheri ea thepa ea thepa e hlahisa thepa e felileng (haholo-holo likarolo tsa aluminium), e sebelisa ts'ebetso ea oxidation ho thatafatsa bokaholimo ba sehlahisoa sa hardware le ho etsa hore ho be thata ho apara.

2. Ts'ebetso ea ho fafatsa pente:fektheri ea lisebelisoa e sebelisa pente ea spray ha e hlahisa lihlahisoa tse kholo tsa hardware, ka ho sebelisa pente ea spray ho thibela hardware ho tloha mafome, joalo ka litlhoko tsa letsatsi le letsatsi, lisebelisoa tsa motlakase, mesebetsi ea matsoho, joalo-joalo.

3. Electroplating:Electroplating hape ke theknoloji e atileng haholo ea ho sebetsa bakeng sa ts'ebetso ea Hardware.Bokaholimo ba hardware bo electroplated ka thekenoloji ea morao-rao ho etsa bonnete ba hore sehlahisoa se ke ke sa e-ba hlobo kapa sa khabisoa tlas'a tšebeliso ea nako e telele.Ts'ebetso e tloaelehileng ea electroplating e kenyelletsa: li-screw, likarolo tsa setempe, Lisele, likarolo tsa koloi, lisebelisoa tse nyane, jj.,

4. Tshebetso ea ho bentša holim'a metsi:Ts'ebetso ea polishing ea bokaholimo hangata e sebelisoa litlhoko tsa letsatsi le letsatsi.Ka phekolo ea holim'a burr ea lihlahisoa tsa hardware, mohlala, re hlahisa khekhe.Kamano ke karolo ea hardware e entsoeng ka ho hatakela, kahoo likhutlo tse hatisitsoeng tsa kama E bohale haholo.Re tlameha ho bentša likhutlo tse bohale hore e be sefahleho se boreleli e le hore li se ke tsa baka kotsi 'meleng oa motho nakong ea tšebeliso.

Nako ea poso: Sep-30-2021