There will be different surface finishes including:

- Grinding

- Polishing

- Bead Blasting

- Electroplating

- Knurling

- Honing

- Anodising

- Chrome Plating

- Powder Coating

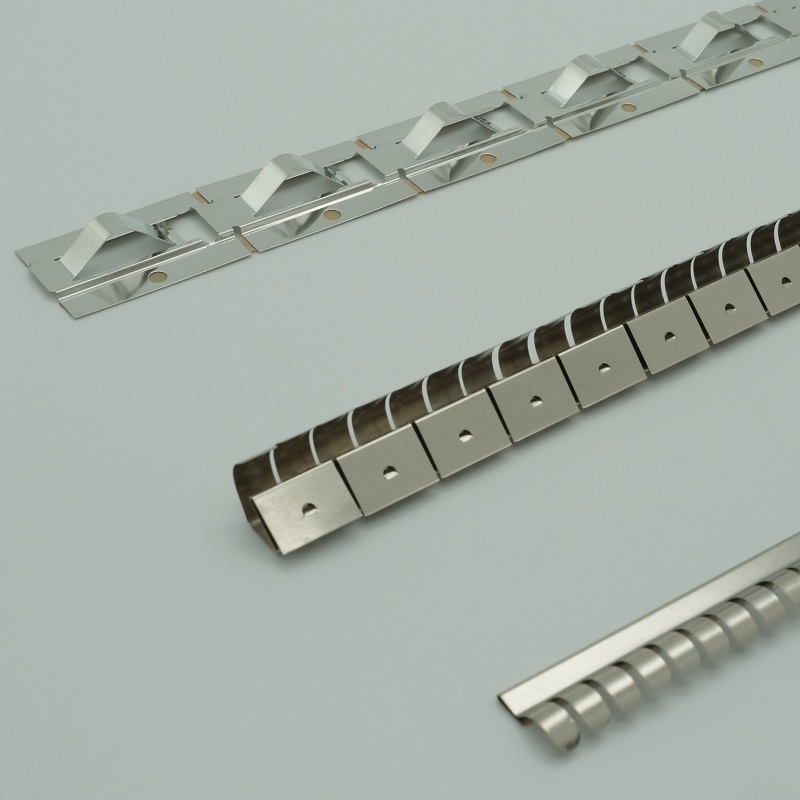

Metal surface processing can be divided into: metal oxidation processing, metal painting processing, electroplating, surface polishing processing, metal corrosion processing, etc.

Surface finishing of hardware parts:

1. Oxidation processing: When the hardware factory produces finished hardware (mainly aluminum parts), it uses oxidation processing to harden the surface of the hardware product and make it difficult to wear.

2. Spray paint processing: the hardware factory uses spray paint processing when producing large hardware products, through spray paint processing to prevent the hardware from rust, such as daily necessities, electrical enclosures, handicrafts, etc.

3. Electroplating: Electroplating is also the most common processing technology for hardware processing. The surface of hardware is electroplated through modern technology to ensure that the product will not be moldy or embroidered under long-term use. Common electroplating processing includes: screws, stamping parts, Cells, car parts, small accessories, etc.,

4. Surface polishing processing: Surface polishing processing is generally used in daily necessities. Through the surface burr treatment of hardware products, for example, we produce a comb. The comb is a hardware part made by stamping, so the stamped corners of the comb It is very sharp. We have to polish the sharp corners into a smooth face so that it will not cause harm to the human body during use.

Post time: Sep-30-2021