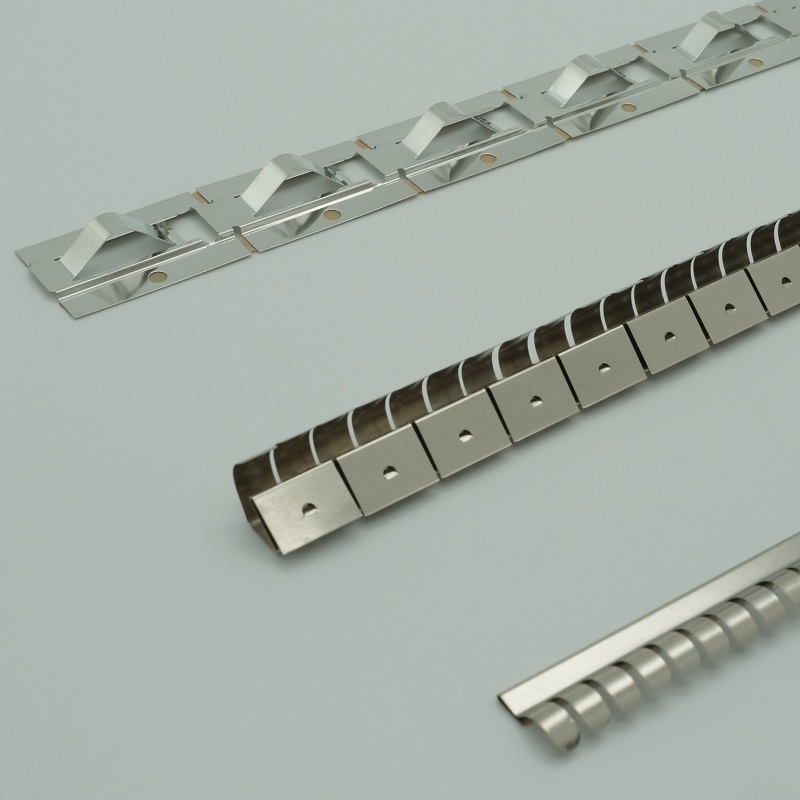

Kuzoba khona ukuqedwa okuhlukile okuhlanganisa:

- Ukugaya

- Ukupholisha

- Ukuqhunyiswa kobuhlalu

- I-Electroplating

- Knurling

- Ukucija

- I-anodising

- I-Chrome Plating

- I-Powder Coating

I-Metal surface processing ingahlukaniswa ibe:ukucutshungulwa kwe-oxidation yensimbi, ukucubungula imidwebo yensimbi, i-electroplating, ukupholisha ubuso, ukugqwala kwensimbi, njll.

Ukuqedwa kobuso bezingxenye zehadiwe:

1. Ukucutshungulwa kwe-oxidation:Lapho i-hardware factory ikhiqiza i-hardware ephelile (ikakhulukazi izingxenye ze-aluminium), isebenzisa ukucubungula kwe-oxidation ukuze iqinise ubuso bomkhiqizo we-hardware futhi yenze kube nzima ukugqokwa.

2. Ukucubungula upende:imboni yezingxenyekazi zekhompuyutha isebenzisa ukucubungula upende wesifutho lapho ikhiqiza imikhiqizo emikhulu yehadiwe, ngokucubungula upende wesifutho ukuze ivikele ihadiwe ekugqwaleni, njengezidingo zansuku zonke, izivalo zikagesi, imisebenzi yezandla, njll.

3. I-Electroplating:I-Electroplating iphinde ibe ubuchwepheshe bokucubungula obujwayelekile kakhulu bokucubungula ihadiwe.Ingaphezulu le-hardware li-electroplated ngobuchwepheshe besimanje ukuze kuqinisekiswe ukuthi umkhiqizo ngeke ukhunte noma ufekethiswe ngaphansi kokusetshenziswa isikhathi eside.Ukucubungula okujwayelekile kwe-electroplating kuhlanganisa: izikulufu, izingxenye zokugxiviza, Amaseli, izingxenye zemoto, izesekeli ezincane, njll.,

4. Ukucubungula kokupholisha ubuso:Ukucutshungulwa kokupholisha ubuso ngokuvamile kusetshenziswa ezidingweni zansuku zonke.Ngokwelashwa kwe-surface burr yemikhiqizo yehadiwe, isibonelo, sikhiqiza ikamu.Ikama yingxenye yehadiwe eyenziwe ngokugxiviza, ngakho-ke amakhona anezigxivizo ekama Ibukhali kakhulu.Kufanele sipholisha amakhona acijile abe ubuso obushelelezi ukuze angeke abangele umonakalo emzimbeni womuntu ngesikhathi sokusetshenziswa.

Isikhathi sokuthumela: Sep-30-2021