1. Ukujula kwembobo nobubanzi

Izimbobo ezimweni eziningi zihlanganiswa nezigayo zokugcina, hhayi ukubhobolwa.Le ndlela yokwenza imishini inikeza ukuguquguquka okukhulu kusayizi wembobo wethuluzi elinikeziwe futhi inikeza isiphetho esingcono sokusebenza kunomshini wokubhoboza.Kuphinde kusivumele ukuthi sisebenzise ama-grooves nama-cavities ngethuluzi elifanayo, ukunciphisa isikhathi somjikelezo kanye nengxenye yezindleko.Okuwukuphela kwecala elibi ukuthi ngenxa yobude obulinganiselwe begayo lokugcina, izimbobo ezijulile kunobubanzi obuyisithupha ziba inselele futhi kungase kudingeke ukuba zenziwe ngomshini kuzo zombili izinhlangothi zengxenye.

2. Usayizi kanye nohlobo lwentambo

Ukubhoboza nokwenza intambo kuyahambisana.Abakhiqizi abaningi basebenzisa "impompi" ukusika izintambo zangaphakathi.Umpompi ubukeka njengesikulufu esinamazinyo futhi "ufaka izikulufu" embobeni ebhojwe ngaphambilini.Sithatha indlela yesimanjemanje yokwenza izintambo, ithuluzi elibizwa ngokuthi i-thread mill lifaka iphrofayili yochungechunge.Lokhu kudala imicu enembayo nanoma yimuphi usayizi wentambo (imicu iyintshi ngayinye) eyabelana ngalelo zwi lingasikwa ngethuluzi elilodwa lokugaya, konga isikhathi sokukhiqiza nesokufaka.Ngakho-ke, imicu ye-UNC ne-UNF esuka ku-#2 ukuya ku-1/2 intshi nemicu ye-metric esuka ku-M2 ukuya ku-M12 konke kungasetshenziswa kusethi yethuluzi elilodwa.

3. Umbhalo engxenyeni

Ingabe ufuna ukuqopha ingxenye yenombolo, incazelo noma uphawu engxenyeni ethile?Ukusheshisa kusekela umbhalo omningi odingekayo ukuze kucutshungulwe, inqobo nje uma isikhala phakathi kwezinhlamvu ezingazodwana kanye nama-stroke asetshenziselwa “ukubhala” okungenani amayintshi angu-0.020 (0.5 mm).Futhi, umbhalo kufanele ube yi-concave kunokuba uphakanyiswe, futhi kunconywa amaphoyinti angu-20 noma ifonti enkulu njenge-Arial, i-Verdana noma i-sans serif efanayo.

4. Ubude Bodonga Nobubanzi Besici

Yonke imimese yethu iqukethe imimese ye-carbide.Lokhu okuqinile okuqinile kunikeza impilo yamathuluzi ephezulu kanye nokukhiqiza ngokuchezuka okuncane.Kodwa-ke, ngisho namathuluzi aqine kakhulu angakhubaza, njengoba kwenza izinsimbi, futhi ikakhulukazi amapulasitiki akhiqizwa ngomshini.Ngakho-ke, ukuphakama kodonga nosayizi wesici kuncike kakhulu kujometri yezingxenye ngazinye kanye nesethi yamathuluzi esetshenzisiwe.Isibonelo, ubuncane besici obujiyile obungu-0.020″ (0.5mm) kanye nokujula kwesici okuphezulu okungu-2″ (51mm) kusekelwa ukwenziwa ngomshini, kodwa lokho akusho ukuthi ungakwazi ukudizayina usinki wokushisa ofakwe ngalezi zilinganiso.

5. I-lathe yethuluzi lamandla

Ngokungeziwe emandleni ethu abanzi okugaya, siphinde sinikeze ithuluzi elibukhoma le-CNC turning.Amathuluzi asetshenziswa kule mishini afana nalawo asezindaweni zethu zomshini, ngaphandle kokuthi singajiki izingxenye zepulasitiki njengamanje.Lokhu kusho ukuthi izimbobo, ama-grooves, amaflethi, nezinye izici zingenziwa ngomshini ngokuhambisana noma i-perpendicular (i-axial noma i-radial) ukuya "ku-eksisi ende" yocezu lomsebenzi oluphendukile (i-Z-axis yalo), futhi ngokuvamile lulandela izingxenye ze-orthogonal ezakhiwe kumashini. isikhungo Imithetho yokuklama efanayo.Umehluko lapha ukuma kwempahla eluhlaza, hhayi ithuluzi elizisethe ngokwalo.Izingxenye eziphendukile njengamashafti namapiston ziqala ziyindilinga, kuyilapho izingxenye ezigayiwe ezifana nama-manifolds, amabhokisi egeji namavalufu ngokuvamile akusetshenziswa, kusetshenziswa amabhlogo ayisikwele noma angunxande esikhundleni salokho.

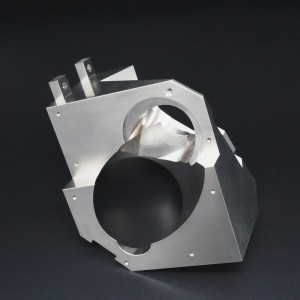

6. Ukugaya ama-multi-eksisi

Kusetshenziswa umshini we-3-axis, ucezu lokusebenza luboshiwe kusukela phansi kwesitoko esingavuthiwe kuyilapho zonke izici zisikwa ukusuka ezinhlangothini ezifinyelela kweziyisi-6.Usayizi wengxenye mkhulu kuno-10″*7″ (254mm*178mm), phezulu nangaphansi kuphela okungenziwa ngomshini, akukho kulungiselelwa okuseceleni!Kodwa-ke, ngokugaya okunenkomba ye-axis emihlanu, kungenzeka umshini kusuka kunoma iyiphi inombolo yamaphethelo angewona ama-orthogonal.

Isikhathi sokuthumela: Feb-15-2022