1. Ho teba ha lesoba le bophara

Likoti maemong a mangata li kenyelelitsoe ka li-mill tsa ho qetela, eseng ho phunngoa.Mokhoa ona oa machining o fana ka phetoho e kholo ka boholo ba lesoba bakeng sa sesebelisoa se fanoeng mme o fana ka sephetho se betere ho feta li-drill.E boetse e re lumella ho kenya li-grooves le li-cavities ka sesebelisoa se tšoanang, ho fokotsa nako ea potoloho le karolo ea litšenyehelo.Ntho e mpe feela ke hore ka lebaka la bolelele bo lekanyelitsoeng ba leloala la ho qetela, masoba a tebileng ho feta li-diameter tse tšeletseng a fetoha phephetso 'me a ka' na a hloka ho etsoa ka mochine ho tloha mahlakoreng a mabeli a karolo.

2. Boholo le mofuta oa khoele

Ho cheka le ho etsa likhoele li tsamaisana.Baetsi ba bangata ba sebelisa "tap" ho khaola likhoele tse ka hare.Theipi e shebahala joalo ka sekurufu se nang le meno 'me "li-screw" ka har'a lesoba le phuntsoeng pele.Re nka mokhoa oa sejoale-joale oa ho etsa likhoele, sesebelisoa se bitsoang khoele se kenya sebopeho sa khoele.Sena se theha likhoele tse nepahetseng le boholo bofe kapa bofe (likhoele ka inch) tse arolelanang sekontiri seo se ka khaoloang ka sesebelisoa se le seng sa ho sila, ho boloka tlhahiso le nako ea ho kenya.Ka hona, likhoele tsa UNC le UNF ho tloha ho #2 ho isa ho 1/2 inch le likhoele tsa metric ho tloha ho M2 ho ea ho M12 kaofela li ka sebelisoa sesebelisoa se le seng.

3. Mongolo karolong

U batla ho ngola nomoro ea karolo, tlhaloso kapa letšoao karolong e itseng?Ho potlakisa ho ts'ehetsa boholo ba mongolo o hlokehang bakeng sa ho sebetsoa, ha feela sebaka se pakeng tsa litlhaku ka bomong le methapo e sebelisoang ho "ngola" bonyane 0.020 inches (0.5 mm).Hape, mongolo o tlameha ho ba concave ho fapana le ho phahamisoa, 'me ho khothaletsoa lintlha tse 20 kapa fonte e kholo joalo ka Arial, Verdana kapa sans serif e tšoanang.

4. Bophahamo ba Lerako le Bophara ba Tšobotsi

Lithipa tsohle tsa rona li na le lithipa tsa carbide.Sesebediswa sena se thata haholo se fana ka bophelo bo botle ba lisebelisoa le tlhahiso ka ho kheloha ho fokolang.Leha ho le joalo, esita le lisebelisoa tse matla ka ho fetisisa li ka holofala, joalo ka litšepe, haholo-holo lipolasetiki tse ntseng li etsoa ka mechine.Ka hona, bolelele ba lerako le boholo ba likarolo li itšetlehile haholo ka geometry ea likarolo tsa motho ka mong le sesebelisoa se sebelisoang.Mohlala, botenya ba bonyane ba 0.020" (0.5mm) le botebo ba karolo e kaholimo ho 2" (51mm) li tšehelitsoe bakeng sa mochini, empa seo ha se bolele hore o ka rala sinki ea mocheso e kentsoeng ka litekanyo tsena.

5. Lathe ea sesebelisoa sa matla

Ntle le bokhoni ba rona bo pharaletseng ba ho sila, re boetse re fana ka lisebelisoa tse phelang tsa CNC turning.Lisebelisoa tse sebelisoang mecheng ena li tšoana le tse litsing tsa rona tsa mochini, ntle le hore ha re fetole likarolo tsa polasetiki hona joale.Sena se bolela hore masoba, li-grooves, lifolete le likarolo tse ling li ka etsoa ka mokhoa o ts'oanang kapa oa perpendicular (axial kapa radial) ho "axis e telele" ea sesebelisoa se fetotsoeng (Z-axis ea eona), 'me hangata li latela likarolo tsa orthogonal tse entsoeng mochineng. setsi Melao e tšoanang ea moralo.Phapang mona ke sebopeho sa thepa e tala, eseng sesebelisoa se ipehetseng.Likarolo tse fetotsoeng joalo ka li-shaft le lipiston li qala ho pota, ha likarolo tse emisitsoeng joalo ka manifolds, mabokose a gauge le likoahelo tsa li-valve hangata ha li sebelise li-blocks tsa lisekoere kapa tse kgutlonne.

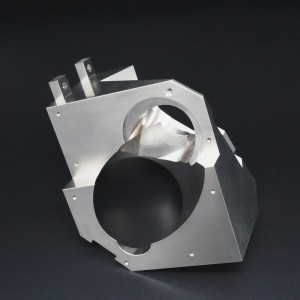

6. Multi-axis milling

U sebelisa machining a 3-axis, workpiece e koetsoe ho tloha tlase ho stock e tala ha likarolo tsohle li khaotsoe ho tloha mahlakoreng a 6 a orthogonal.Boholo ba karolo e kholo ho feta 10 ″ * 7 ″ (254mm * 178mm), ho ka etsoa feela holimo le tlase, ha ho na tlhophiso ea lehlakore!Leha ho le joalo, ka ho siloa ha li-axis tse hlano, hoa khoneha ho sebelisa mochine ho tloha palo efe kapa efe ea likarolo tse seng tsa orthogonal.

Nako ea poso: Feb-15-2022